1. Product Introduction

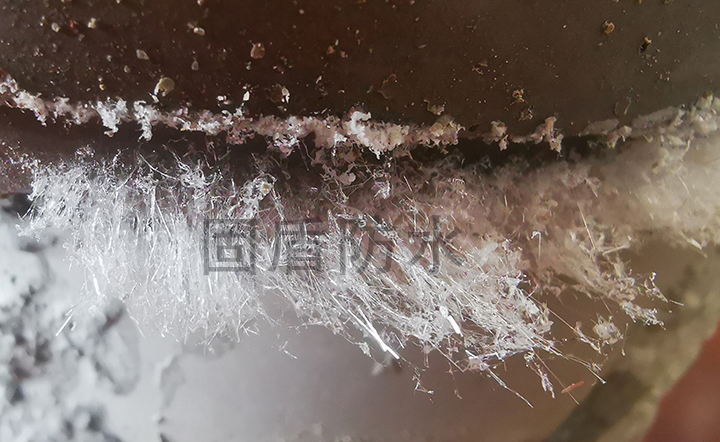

Solid Shield Liquid DPS is a penetrating crystalline waterproof preservative that combines hydrophilicity, water absorption, and water repellency. It is colorless, transparent, non-toxic, odorless, and harmless to humans and the environment. It can deeply penetrate into the interior of concrete, react with free alkali to crystallize, fill the capillary pores and cracks of concrete, and form an overall structural seal. The surface's water repellent properties block the infiltration of water and dirt, without changing the color and texture of the concrete, providing dual protection and long-lasting waterproof and anti-corrosion effects.

Crystallization real shot

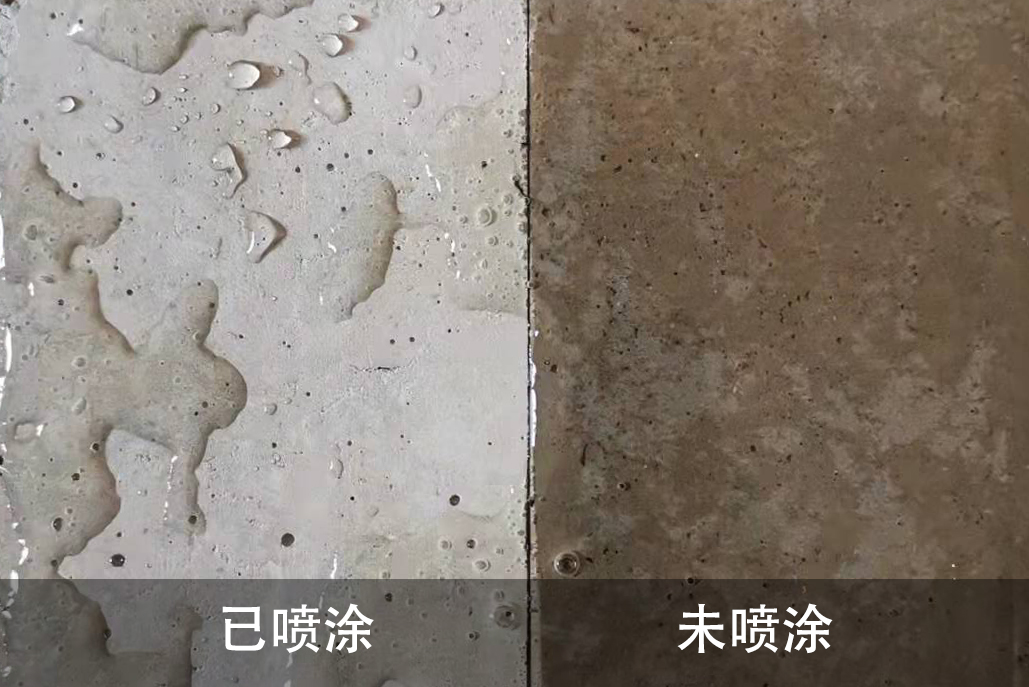

Excellent water repellency of concrete surface

2.Waterproof mechanism

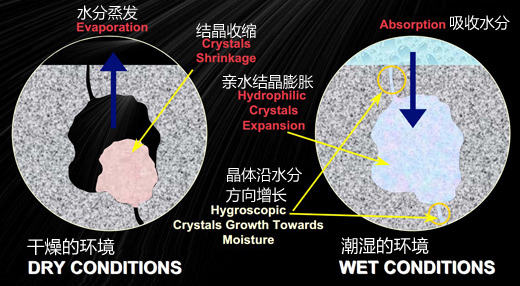

The solid shield liquid DPS achieves its protective effect through two different mechanisms. Firstly, it endows the construction surface with repulsive properties, enhances the surface tension of water and other liquids, and prevents water from seeping into the interior of the concrete through capillary tubes. Through the crystallization process, capillaries are sealed inside the concrete to prevent the movement of water and moisture. The formed crystals have both hydrophilicity and water absorption, thus possessing a dual moisture barrier effect. In humid environments or in contact with moisture, the water absorption of the solid shield liquid DPS causes crystal expansion and fills pores, thereby preventing the extension of moisture. Meanwhile, the hydrophilicity of crystals allows them to continuously grow along the direction of the moisture source, forming a moisture barrier at the moisture source. In dry conditions, during the desorption process, the crystals release moisture and shrink to their initial size. The expansion/contraction properties of crystals can allow concrete to continuously breathe, ensuring its healthy state.

3. Functional features

◎ No need for leveling layer and protective layer.

Low construction cost and fast construction progress.

◎ Will not age, the effect is very stable, and has the same lifespan as concrete.

Traditional problems such as loose overlap and peeling will not occur.

◎ Can be used for waterproofing in drinking water pools, swimming pools, and home decoration.

Can replace silane for concrete protection.

The surface is water repellent and self-cleaning, preventing the infiltration of water and stains.

Waterproof and anti-corrosion, moisture-proof and mildew proof, acid and alkali resistant, chloride ion resistant, and frost resistant.

Cracks below 0.8mm in self-healing concrete.

Has extremely strong resistance to water pressure and immersion.

Improve the strength and compactness of concrete.

Effectively alleviate the alkali aggregate reaction in concrete.

Protect the surface of concrete from powdering easily.

Both the upstream and downstream sides can be used.

The expansion and contraction of crystals ensure the breathability of concrete

4.Why does concrete need waterproofing and anti-corrosion

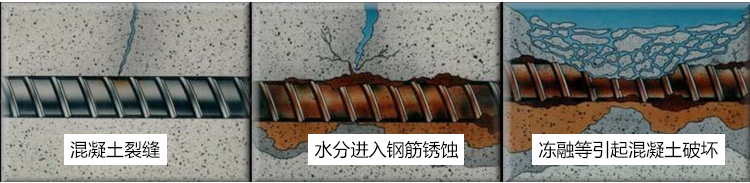

Architects and engineers are aware that if concrete and cement surfaces are not properly treated and protected, they will quickly peel off or crack, and rainwater, salt, and grease entering the pores of the concrete will cause significant damage to the concrete surface and steel bars in the concrete. These pores, like water pipes, transport surface rainwater, salt, and grease to the interior, causing significant damage to the structure of concrete and cement. After multiple freeze-thaw cycles, rainwater, salt, and grease will accelerate the corrosion of steel bars and the deterioration of the structure in concrete. We usually don't immediately notice these signs of damage, but when the structure breaks, these marks will quickly appear. The solid shield liquid DPS can resist the damage of rainwater, salt, and grease and protect the concrete well.

5. Application scope

All concrete buildings and components

◎ Highways, bridges, tunnels, and subways

◎ Drinking water pool, swimming pool, sewage pool, fire water pool

Airports, docks, and maritime engineering

◎ Dams, canals, and water conservancy facilities

Foundation, ground, basement

◎ Factories, power plants, cooling towers

6. Instructions for use

1. After inspecting and repairing vulnerabilities and cracks, clean the base surface thoroughly.

2. Shake well before use, shake for about one minute.

3. Do not dilute or mix with any other liquid for use.

4. When it is dry or slightly wet, it can be sprayed or brushed with a low-pressure spray.

5. The dosage is 3-4 square meters/kg, and only one saturated spray is needed.

6. The optimal construction environment temperature is 5-35 ℃ and humidity is 10% -90%.

7. Ensure that there is no rain within 24 hours after construction.

8. The closed water test can only be conducted after 3 days of natural maintenance.

9. If there is slight seepage, it will gradually seal and dry on its own.

10. If frozen, it can be used normally after melting.

7. Precautions

1. Do not dilute or mix with any other liquid for use.

2. Do not touch glass or aluminum products.

3. Not suitable for surfaces treated with paint or other coatings.

4. Avoid eye and skin contact and keep away from children.

8. Storage and Quality Assurance

1. The product is stored in a cool and dry environment.

3. Shelf life of 10 years in the original sealed state.

|